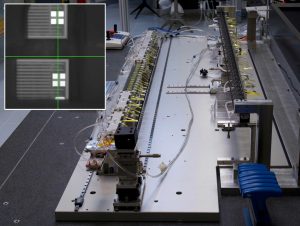

The ALICE ITS (Inner Tracker System), with a total of 12,500 megapixels and an exstention of 10 square metres, can be considered the world largest “digital camera”. Based on a bleeding-edge sensor technology (MAPS, Monolithic Active Pixel Sensors), it integrates on a single ultra-thin chip (50-100 microns) the sensor and readout electronics, featuring world-record performances in terms of spatial resolution and data rate. The LNF-ALICE team is strongly committed to the construction of ITS. The LNF production site, together with other labs in US, UK, NL, and the INFN Section of Torino, is providing a significant part arranged in 1.5m-long modules (carbon fiber structure called staves) for the outer layers of the ITS: this part already surpasses – in terms of surface – any silicon detector presently in operation. The completion of ITS is foreseen for mid 2019.

The ALICE ITS (Inner Tracker System), with a total of 12,500 megapixels and an exstention of 10 square metres, can be considered the world largest “digital camera”. Based on a bleeding-edge sensor technology (MAPS, Monolithic Active Pixel Sensors), it integrates on a single ultra-thin chip (50-100 microns) the sensor and readout electronics, featuring world-record performances in terms of spatial resolution and data rate. The LNF-ALICE team is strongly committed to the construction of ITS. The LNF production site, together with other labs in US, UK, NL, and the INFN Section of Torino, is providing a significant part arranged in 1.5m-long modules (carbon fiber structure called staves) for the outer layers of the ITS: this part already surpasses – in terms of surface – any silicon detector presently in operation. The completion of ITS is foreseen for mid 2019.

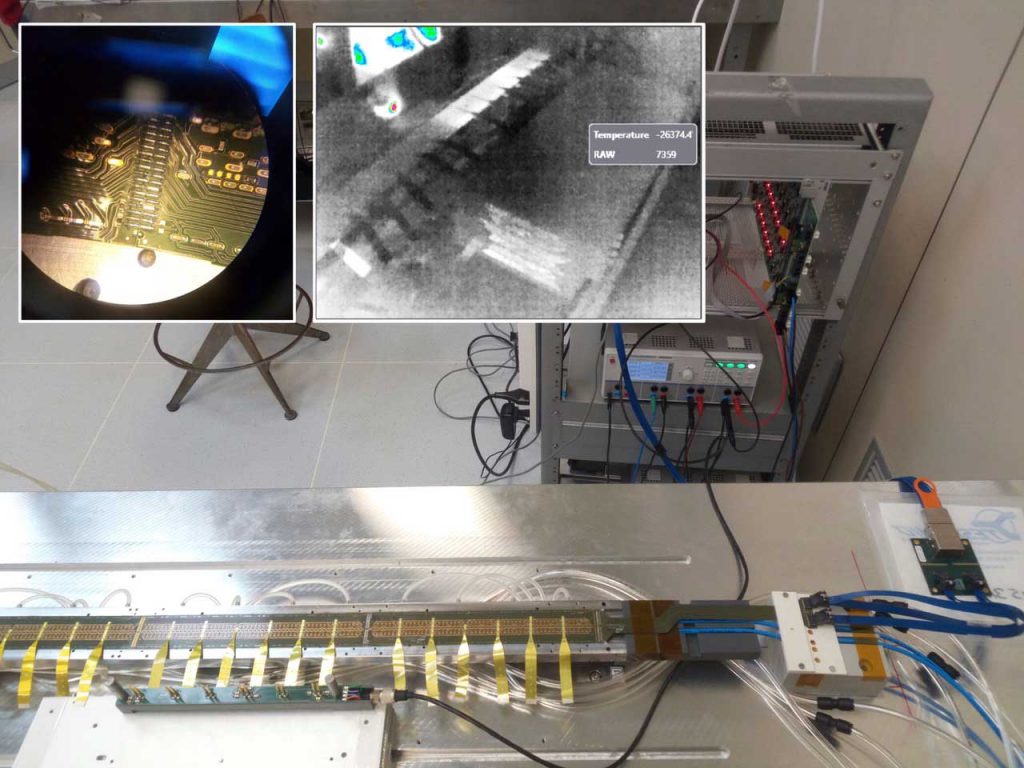

Recently, after an intense development work, the ALICE LNF team was able to produce and test its first functional unit. During the last 18 months all the aspects of the production chain were developed: from mechanical alignment and processing of silicon sensors with precisions of the order of a human hair, to the electro-mechanical testing and qualification of the sensors. These achievements were possible thanks to the continuous support of Frascati Laboratories and the MAECI funding which made possible the realization of the dedicated infrastructure.

After its “twin” site of Torino, LNF are the first outer layers ITS production site to assemble, power on, readout and test a functional half stave. This success confirms the INFN global leadership in the field of silicon sensors for high energy physics, and it’s particularly relevant for the LNF since this technology development started at the Frascati Laboratories only in recent years.

Translation by Camilla Paola Maglione, Communications Office INFN-LNF

INFN-LNF Laboratori Nazionali di Frascati

INFN-LNF Laboratori Nazionali di Frascati